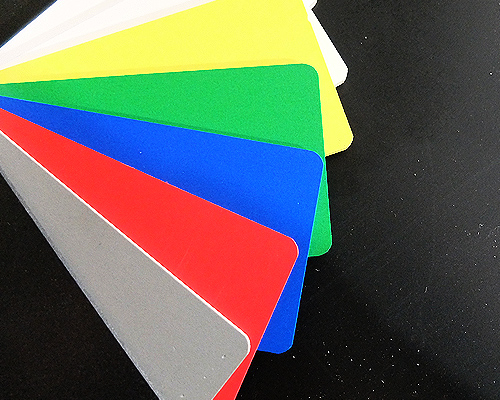

Foam PVC is a highly versatile light weight material ideal for your indoor signage needs. It is an extruded product which has a matte surface suitable for a variety of applications. Foam PVC is used for advertising and non-illuminated signboards, point of sale, cut out lettering, partitions and shelving, furniture, electronic control panel backing boards.